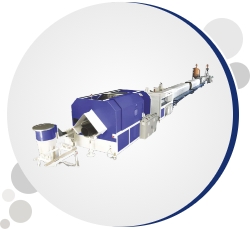

PVC Pipe Plant

UPVC being a heat sensitive material necessitates a very controlled temperature during processing.

Windsor twin screw extruders are known for the power optimization and are offered in the range from 110 Kg/hr up to 1500 Kg/hr.

Features

- Minimizes energy inputs

- Achieves uniform pumping

- Two piece barrel construction

(a) Front barrel with HSS sleeve offered as standard, minimizes wear & tear

(b) Economic replacement option - PLC controls as standard

- Hard face tungsten carbide coating on flight ends in metering zone for high wear resistance- standard and full encapsulation [Optional].

HDPE Pipe Plant

Understanding extrusion market requirements thoroughly, Windsor extruder takes lead in technical superiority.

The screw and barrel are designed and developed to match specific raw material and end product requirements by simulation software.

We offer barrier screws yielding improved output rate, low melt temperature and improved melt quality.

- 4th generation energy efficient extruder

- European Proven Technology ensures excellent linearity of specific output

- UD ratio of 37 :1 ensures excellent melt homogeneity

- Grooved feed design extruder. Versatile screw designed for PE & PP Random Copolymer

- Direct coupled design ensures minimum transmission loss

- Wear resistant Tungsten Carbide coating ensures long screw life at high rpm

PPR Pipe Plant

- 4th generation energy efficient extruder

- European Proven Technology ensures excellent linearity of specific output

- UD ratio of 37 :1 ensures excellent melt homogeneity

- Grooved feed design extruder. Versatile screw designed for PE & PP Random Copolymer

- Direct coupled design ensures minimum transmission loss

- Wear resistant Tungsten Carbide coating ensures long screw life at high rpm